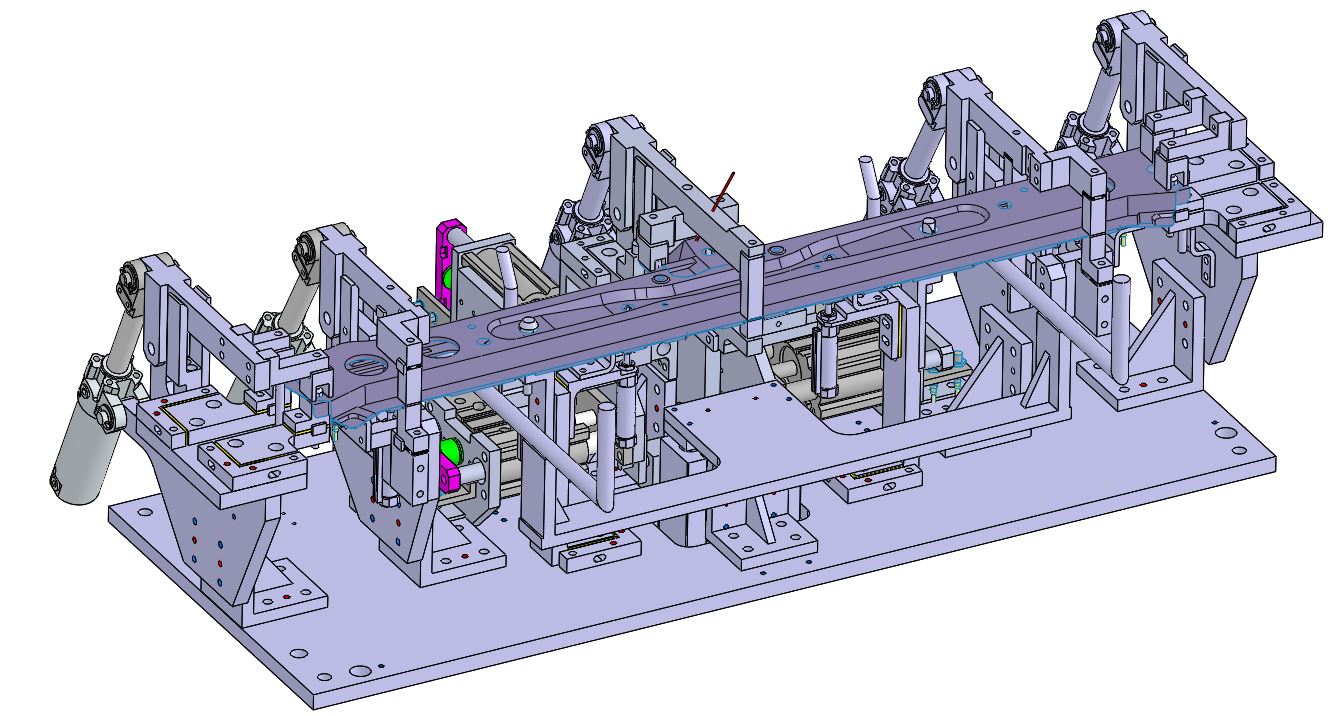

1. Welding Fixture Design

Due to various needs in time, new welding fixtures have to be designed and produced in our factory. After the designs are shaped in 3D environment, component productions are made From the completion of the assembly, trials are carried out until compliance with the quality standards is ensured, after these trials, welding jigs are started to be used in mass production

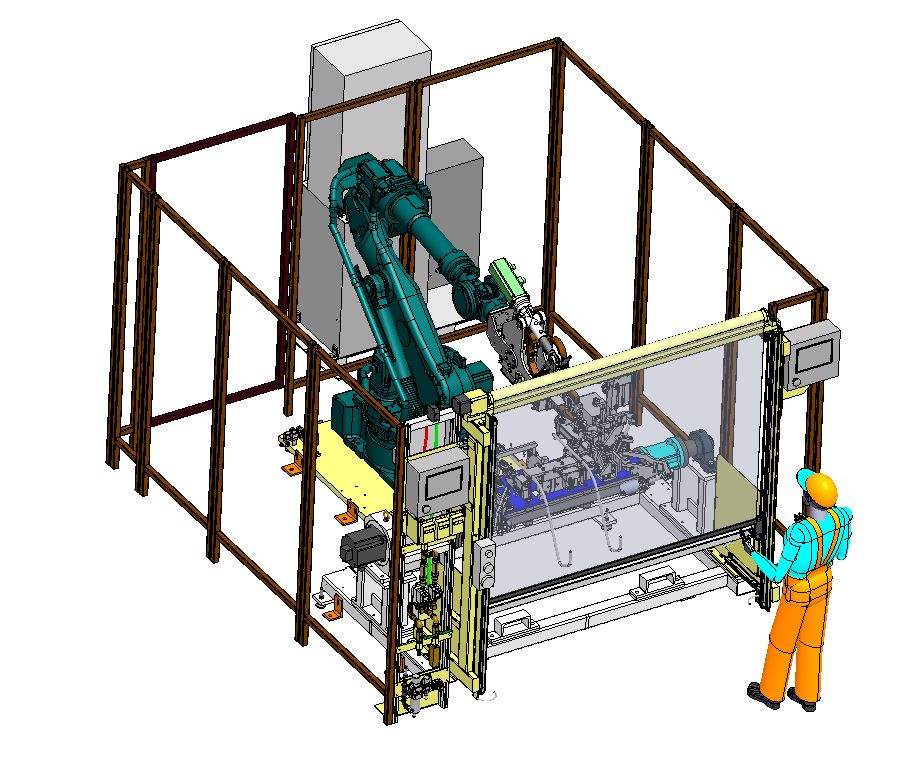

The upper part, which was previously produced manually, has been produced in robotic automation since January 2008 with the design, production and commissioning of the welding jig required for automation

The upper part jig, which is currently being produced on the manual line is stnned to start automatic production as of July 2010, after the design and production phases are completed.

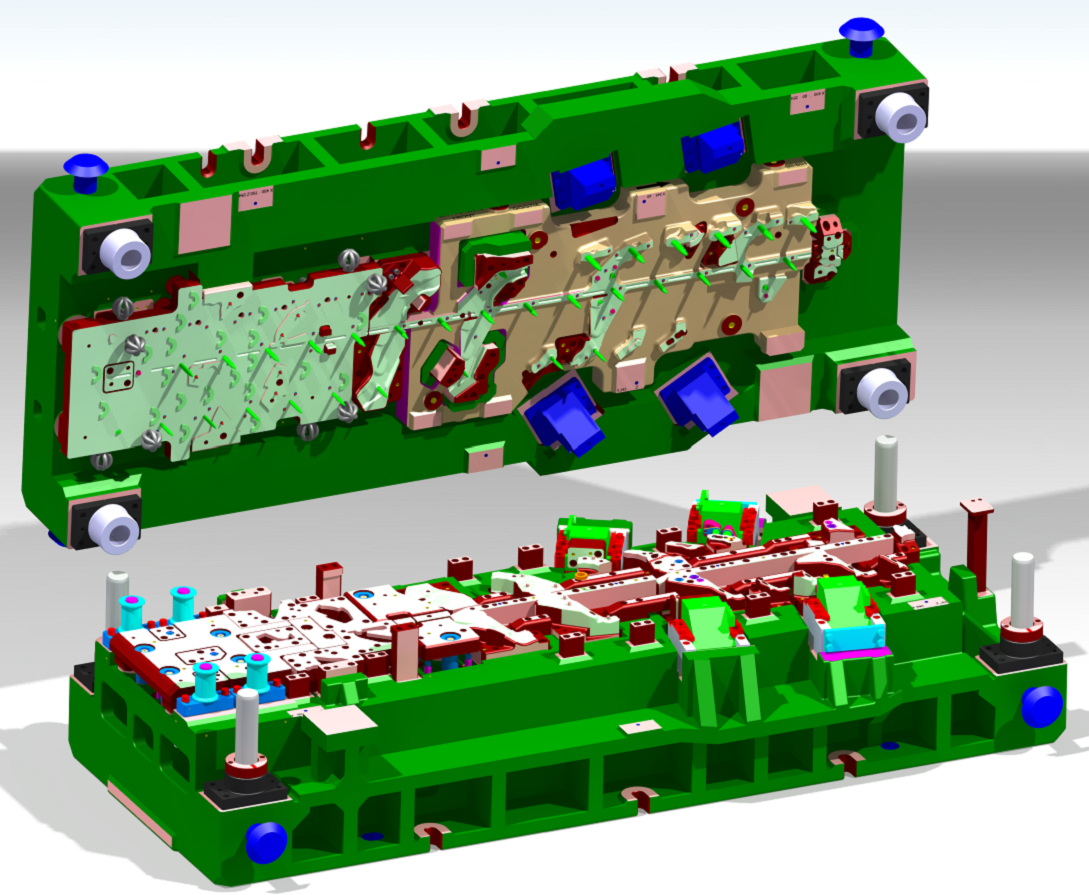

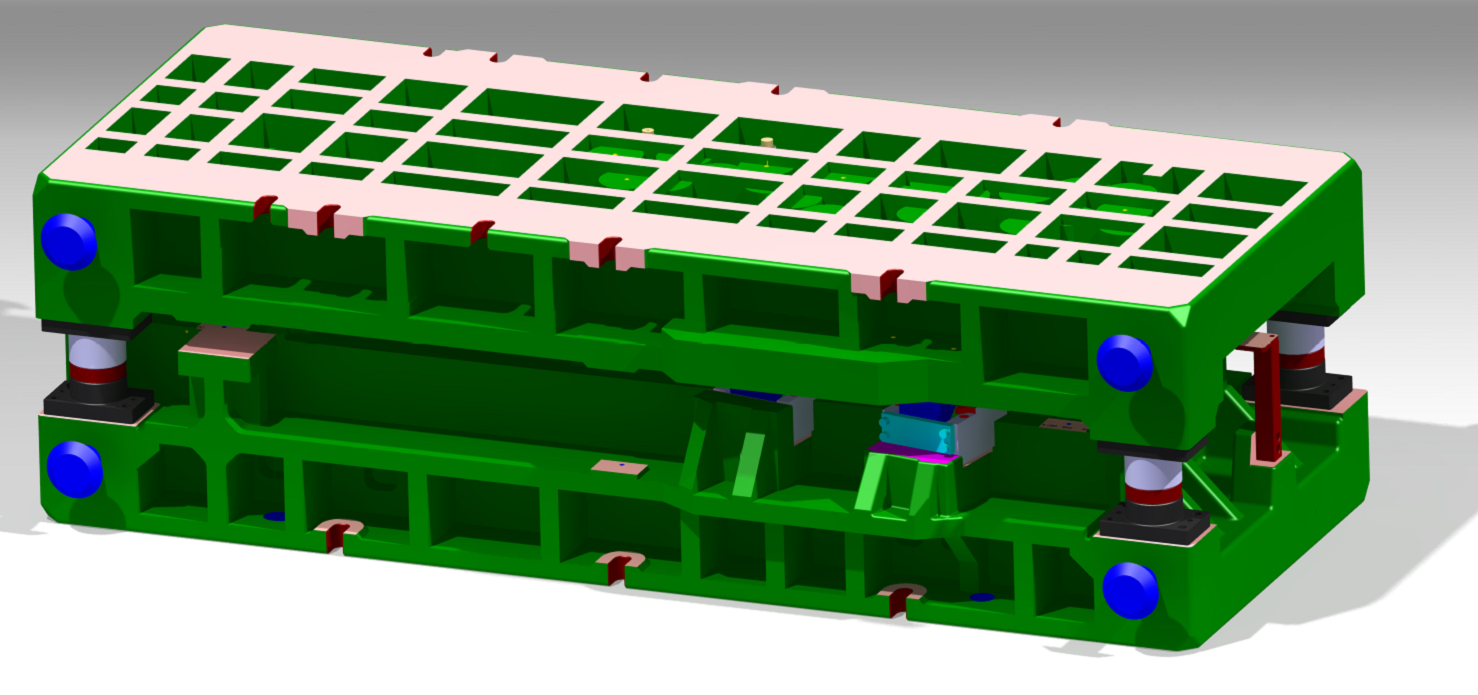

2. Part Data

The part data, technical drawings are examined in detail and the most suitable processes are decided by making simulations with the Autoform software. According to the Toyotetsu Die Standarts and press machine specifications 3D die design is done with Catia software,

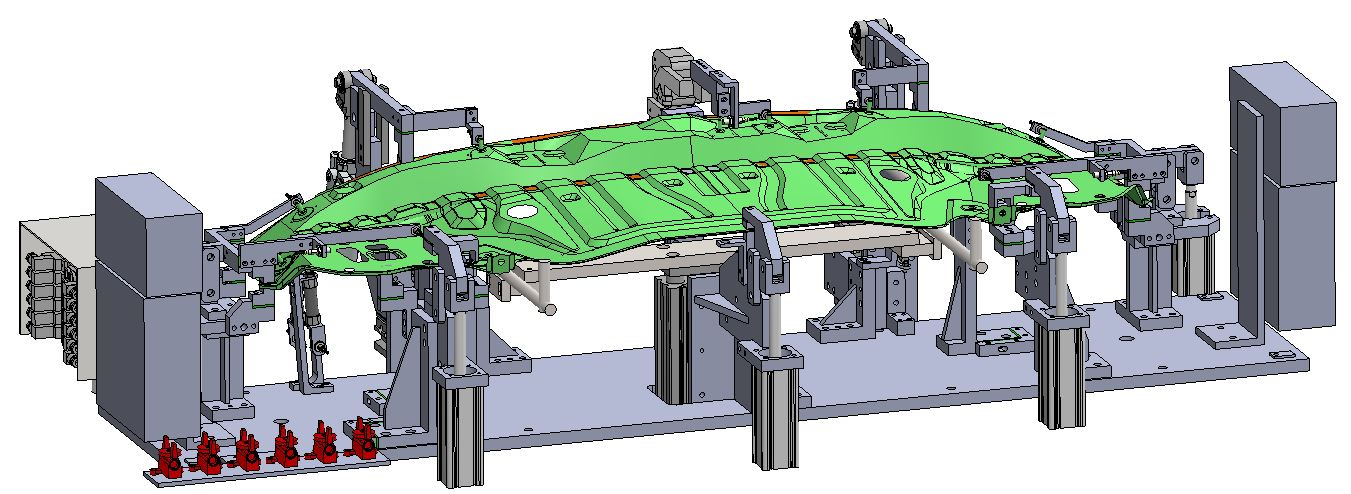

3. Production Line Design

These operations could be outlined under 4 section.

3.1 Process Design: Production method (manual or robotic) is decided according to part 3D data and technical drawing.

3.2 Layout determination: The location of the production line is requested close to the assembly line and final quality control area. Logistic operations are also

considered while making lay out design.

3.3 Man power and Cycle Time Calculation: Calculation method is determined according to process quantity, part cycle time and production volume of part.

3.4 Equipment Selection: it is decided which welding machine or which welding robot will be used. The welding machine is chosen according to the material

properties of the part that be produced, the speed of sales of the part, and the maintenance costs. The robot selection is made by considering pay-load,

maintenance costs, reliability and repeatability of the welding equipment it will carry

In this application, it is aimed to automate the manuel spot lines to robotic welding line for CT decreasement and ergonomic improvement.