TOYOTETSU Production Philosophy

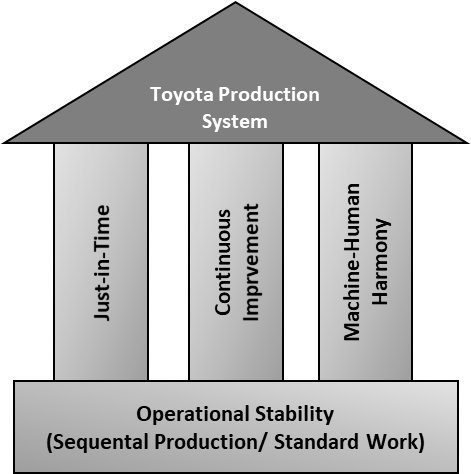

The Toyotetsu Production System is based on the philosophy of providing the products in best quality at the low cost to meet customer demands in the exact time of request. In line with this philosophy, we use the Toyota Production System, which is our best guide as a tool, while we carry out our production.

The 3 main pillars of our production system, which is based on operational stability, can be summarized as follows:

1. Just-in-Time Production and Shipment (Just-in-Time)

2. Machine-Human Harmony (Jidoka)

3. Continuous Improvement (Kaizen)

The details of these 3 main pillars are summarized as below:

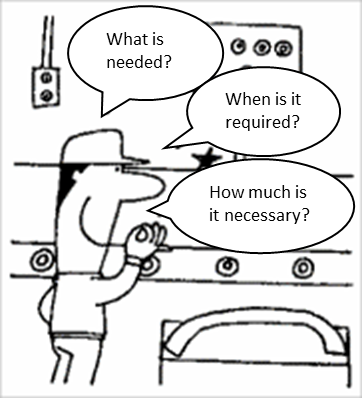

1. Just-in-Time (The right part at the right time in the right amount)

1.1 To produce in the shortest time when there is demand

Short lead time (it starts with receiving orders from customer and finishes with the shipment)

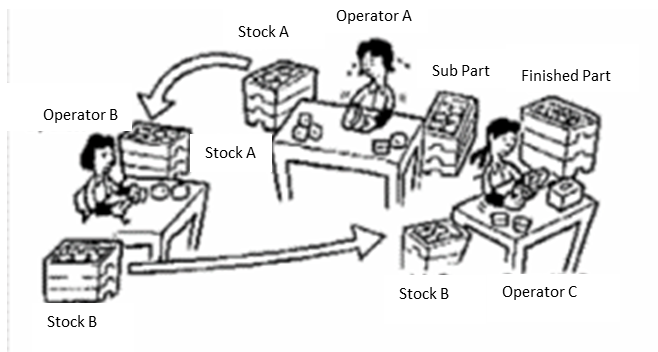

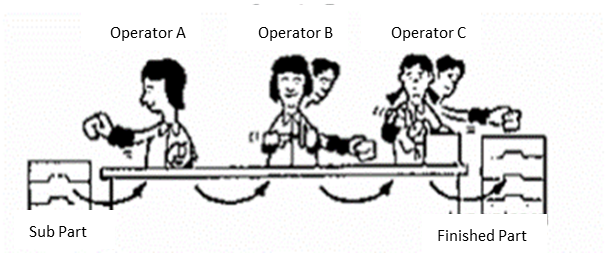

1.2 Sequential Production (Heijunka)

Balancing quantity and variety in a sequential production order

1.3 Basic Operation Rules

- Continuous flow (one piece flow)

- Standardized Work

- Pull System and Kanban

- Production in Required Quantity (Takt time)

2. Machine-Human Harmony (Jidoka)

The aim of Jidoka is to provide a good harmony between machine and human, to produce low-cost, best quality products by producing quality during production and preserving manpower.

The difference between jidoka and automation can be exemplified by the operator can do a manual job on another machine while the machine is doing the job.

3. Continuous Improvement (Kaizen)

Improvement (kaizen) has become a philosophy of life at TOYOTETSU. With the idea of "There is no end to improvement", the current situation is always examined and aimed to improve.

Minimum Stock Level

Thanks to our production system, which has been shaped in line with our philosophy summarized above, stocks are kept at low levels that it can be expressed with shifts for in-plant safety stocks and a few hours for shipment.